Composite Mode – end use performance for both strength and serviceability criteria Because it is suspended, are you using removal and integral form?Whether your columns are for structural purposes or intended as a modern design feature, West Sydney Formwork have the experience and capabilities you require Mezzanines are the best way to create more floor for space for your business and building Our suspended concrete slabs are durable, versatile and weight bearing

Q Tbn And9gcstfx Rzcjfxnpwdzm9ih1flj47wyelb0j8gzsjt9jw Xwpgsin Usqp Cau

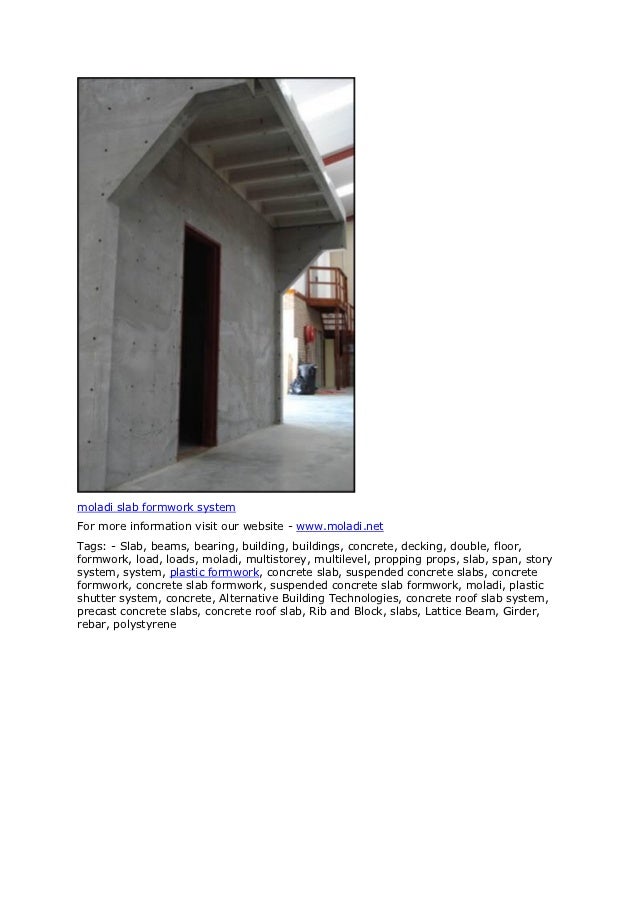

Suspended concrete slab forms

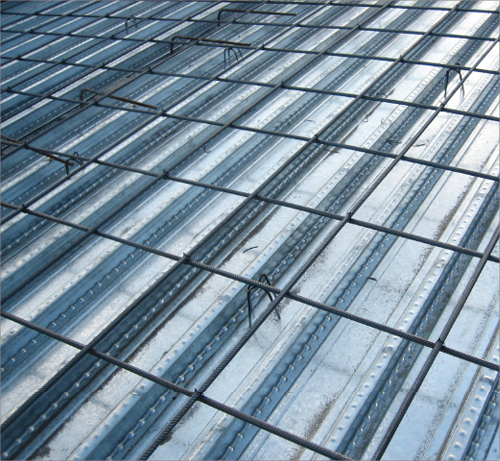

Suspended concrete slab forms-Column formwork and pouring concrete on site work activities carried out in a factory environment are generally lower risk table or flying forms—a large preassembled formwork and falsework unit often forming a complete bay of suspended floor slab, and modular formwork systems which are often lighter weight and eliminate the need for tasksConcrete slab Suspended slab formwork and rebar in place, ready for concrete pour A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steel reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while

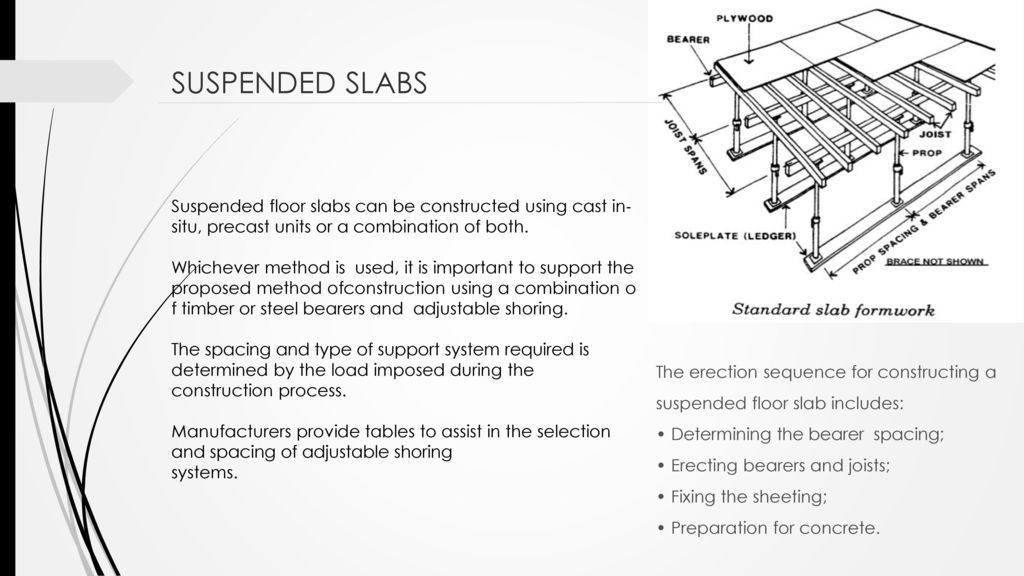

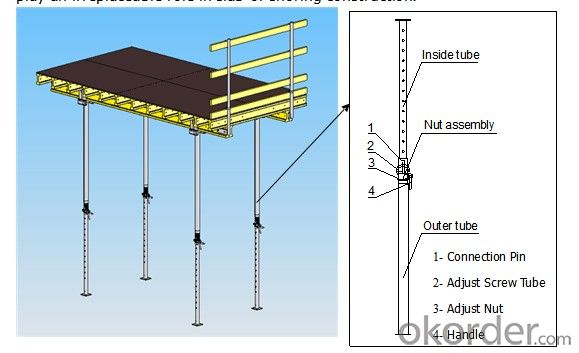

Formwork Bearers

Curing a concrete slab involves the application of water over an approximate 7 day period Applying moisture to the concrete helps it to seal Spraying twice daily is ideal – use light mist sprays with complete coverage After 24 hours of the concrete being poured, the formworkTraditionally column spacings and floor spans in these buildings have been in the range of 6 to 9 metres, to both contain costs and simplify construction However, recently there is a preference for large floor areas with columnfree space and spansSuspended slabs are formed and poured in situ, with either removable or 'lost' nonloadbearing formwork, or permanent formwork which forms part of the reinforcement Precast slab They can be made from conventional or posttensioned reinforced concrete, or from autoclaved aerated concrete (AAC) (see Autoclaved aerated concrete)

A Smartslab suspended concrete floor is noncombustible therefore making it ideal for those building in bush fire prone areas TOTAL SERVICE SMARTSLAB provides a total service for the design and construction of suspended slabs Each slab is individually designed and all our work is installed and certified by an experienced SMARTSLAB teamSuspended Concrete Slabs Formwork Systems Of course, that quickly scrawled drawing is accurate, but it doesn't exactly overflow with details Logistically, a number of formwork components need to be moved up to each floor before the suspended concrete slabs can beThe present invention relates to a formwork arrangement for forming a suspended concrete floor slab comprising a change in level in an underside thereof, a support bracket for use with such a formwork arrangement, and a method for employing the support bracket and formwork

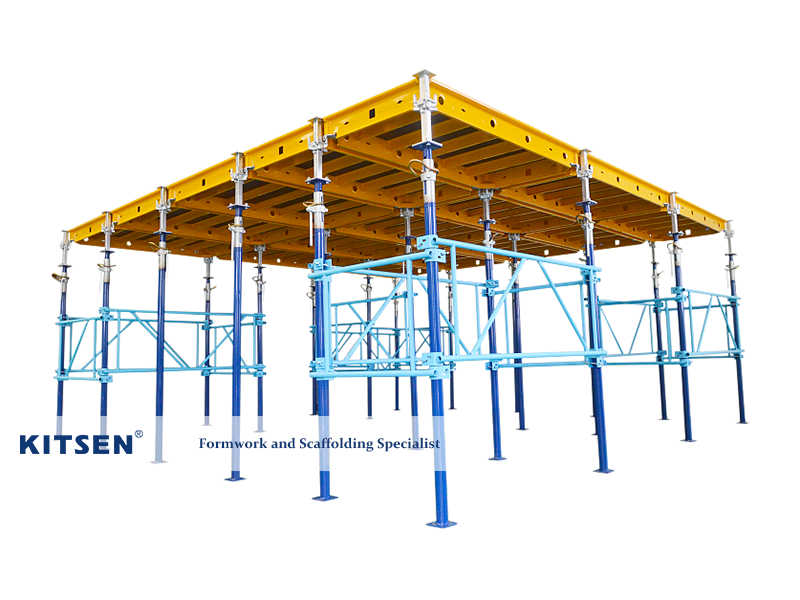

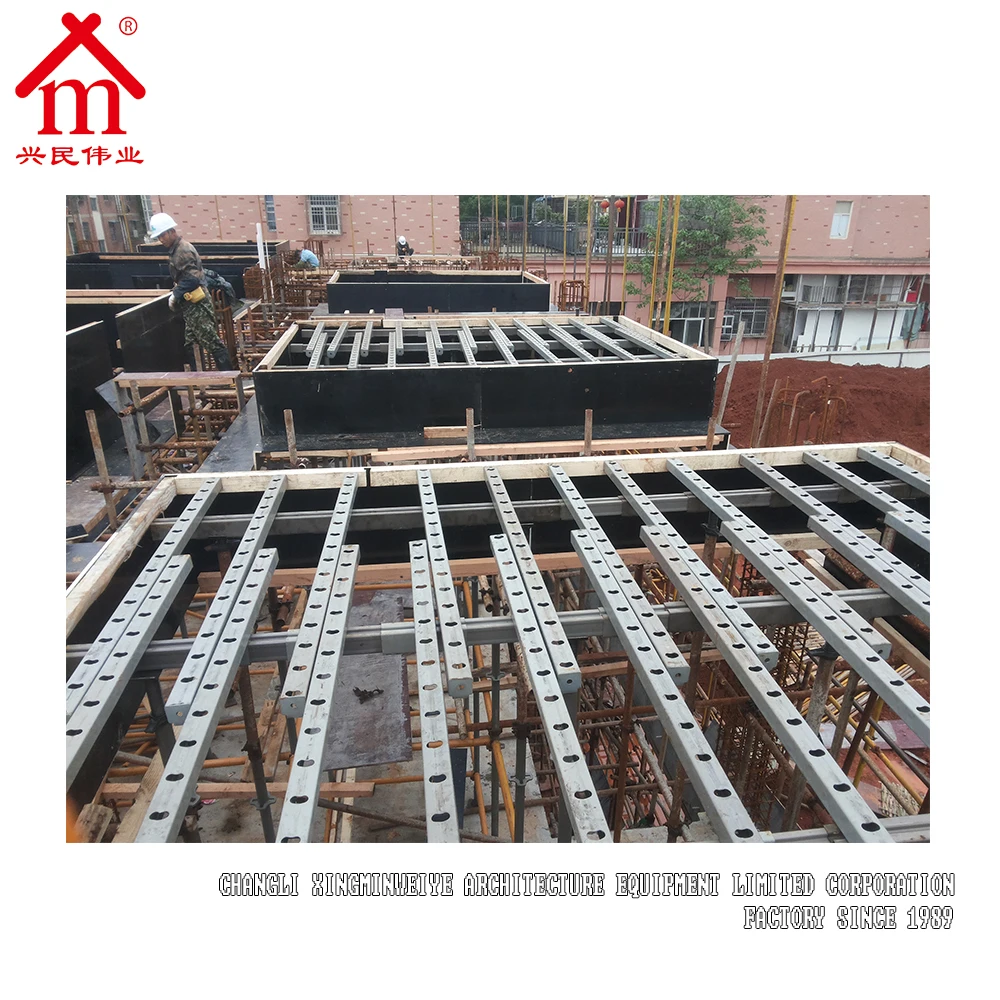

Twice the strength of traditional material this 100% reusable aluminum solution will reduce project costs and impact on the environment The EdgePro slab formwork system was developed to simplify the erection of slab formwork construction on granular bedding, existing excavated ground, concrete surfaces, suspended slabs and tilt panel fabrication Suspended Slab Formwork what is it and applications Suspended slab formwork is formed and cast onsite, and this is done with removable or nonloadable formwork s or permanent formwork s that form part of the reinforcement Therefore, to produce a suspended slab formwork, we need precise formwork, which can be selected from two different typesSuspended slab formwork Manufacturers Directory find 12 suspended slab formwork from suspended slab formwork online Wholesalers for your sourcing needs from China

Commercial Concreting Bampak

Mevadec Meva Formwork Systems

Suspended Slab Formwork Systems Cassaform offers a full range of slab formwork systems for your next concrete slab From traditional Super Shore formwork frames through to our new aluminium pan system, we can help you find the best system for your next Formwork jobSlab formwork is used to construct a suspended concrete slab that is not directly supported by the ground It acts as a mold in which fresh concrete can be poured in so that it can get a desired shape and size When a slab is suspended, the formwork's job is to support the concrete of the slab till it is perfectly curedGibson Building installed a suspended concrete slab formwork system in a residential project in Agnes Water, Queensland Gibson Building trialled a new formwork system supplied by Form Direct in Bundaberg The 'Proshore Formwork System' which was erected by Gibson Building is an innovative formwork system out of the USA The formwork was

Concrete Slab Wikiwand

Concrete Slab Floors Yourhome

Formflex is a temporary works system to facilitate the forming and support to suspended concrete slabs The system concept is to provide a simple straight forward and safe solution for the customer whilst providing a versatile solution for a variety of slab thicknesses and shapes to construct By using a standard 2m x 1m grid the Formflex givesWe're skilled in all types of formwork systems We can help you with the planning process and throughout the construction works to deliver a quality job on time Our structural formwork systems include Conventional Formwork AFS Rediwall/Dincel In situ concrete works Condeck/Bondek Suspended slabs and beams Concrete tilt panel systems🕑 Reading time 1 minuteConcrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab ContentsConcrete Floor Slab Construction Process1 Assemble and Erect Formwork for Slab2 Prepare and Place Reinforcement for Slab3 Pour,

5 Things To Look For When Inspecting A Suspended Concrete Slab

Suspended Concrete Slab Suspended Slab Cement Slab

Metal Floor Deck Steel Decking Formwork provides a fast, efficient method of creating suspended concrete slabsThe composite action of steel decking also increases efficiency by forming a higher performance composite slabIt offers excellent spanning Normally, formwork is designed to support load from fresh concrete (including static pressure), their self weight, live load from working personnels, and load from other equipment A typical formwork configuration for floor slabs is shown in the figure below;I would imagine that the formwork stays in place – whatever is cheapest for this One part of the quote says $300/m3 allowance for concrete mix for top level slab How much is the quote?

Design And Calculation Of Formwork Requirement Of Slabs Structville

Formwork For Decks And Floors Concrete Construction Magazine

Practical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columns Suspended slabs are upper floor slabs that are not in direct contact with the ground and form the roof or the floor above the ground level They usually form the upper stories house floors but can also be laid on top of a prebuilt wall to form a floor Concrete slabs come in many forms and can be used to provide great thermal comfortHold suspended formwork for set downs, rebates and steps on concrete slabs The Screedmaster chair is designed to hold forms on metal decks and/or conventional formwork decks The base can be fastened down using staples, nails or screws It has an adjustable threaded height range of 125mm 245mm

Formwork Ppt Download

Structure Suspended Slab Home Building In Vancouver

Working Together One Structure is a Brisbane based formwork company specialising in Speedfloor, a completely propless lightweight suspended concrete slab system We can also cater for all types of formwork and allinone reo and concreteUNIT DESCRIPTOR CPCCCA3019A Erect and dismantle formwork to suspended slabs, columns, beams and walls This unit of competency specifies the outcomes required to erect and dismantle formwork to suspended slabs, columns, beams and walls to contain concreteI am guessing $3040k for the slab Well this is the problem We don't know

Formwork Products Largest Suppliers Of High Quality Plywood Products

Flying Table Formwork For Large Area Slab Concrete Construction

Design of the suspended slab using the Stramit Condeck HP ® Composite Slab System requires analysis of three separate functions Formwork Mode – including laying of the decking, propping (if required), concrete pouring and curing, and incidental use during this time such as stacked material loading;Step 6 Erect formwork for the slab along the outer edges of the building footprint The formwork will provide the shape of the slab and hold the concrete while it dries Step 7 Lay polythene sheeting and tape Step 8 Lay steel reinforcement fabric and trench mesh for the slab Step 9 Pour concrete in one operation creating a slab thatSuspended Slab on Metal Deck A quick and easier way to build suspended slab is to use metal deck if it's accessible This approach to concrete slab construction is very common in commercial construction Using metal deck as forms for cement slabs over garages is a great alternative to building forms with wood and/or scaffolds

Structure Suspended Slab Home Building In Vancouver

1 7 Support Slab Photos Free Royalty Free Stock Photos From Dreamstime

Suspended concrete slabs It's made from hightensile steel offering high spanning capabilities The durable galvanised Equal formwork spans Slab span Concrete slab L L L L L Formwork joints over permanent supports only Slab span Equal formworkSuspended slabs are slabs that are not in direct contact with the ground They form roofs or floors above ground level Suspended slabs are grouped into two types one way slabs which are supported on two sides two way slabs which are supported on all four sides What is the minimum thickness for a concrete slab?Steel Formwork TRUEDEK ® is a permanent steel suspended slab formwork system that provides significantly more features and a number of additional benefits compared to existing steel formwork and metal decking systems Installation Download your Installation Guide, including prestart needs, detailing requirements, safety instructions and

Suspended Slab Formwork Cassaform Construction Systems

Kingflor Kf57 Fielders

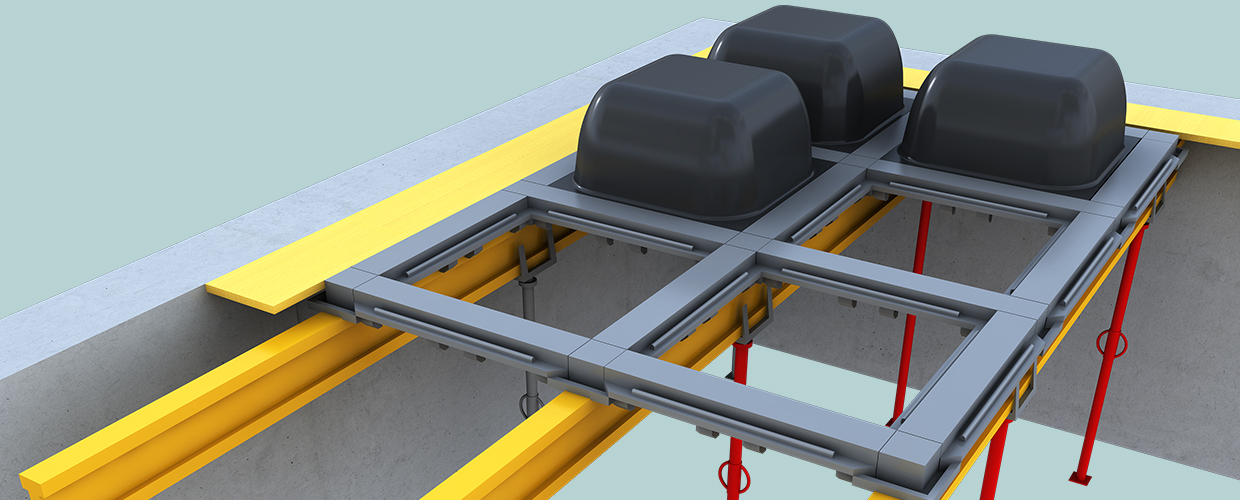

Dokadek 30 is a beamless, handset formwork system designed as a lightweight steel structure with yellow coated frames faced with timber/plasticcomposite sheeting Dokadek 30 combines the advantages of a panel floor formwork system with those of Dokaflex floorslab formworkPermanent Formwork becomes part of slab reduces propping, formwork stripping and bottom reinforcement Fire Rating Benefits FD300 unique closed rib profile reduces FER(fire emergency reinforcement) when encased in concrete High Tensile Steel light weight with high strength reduces propping simple to installAn overview of the structure types for suspended slabs and grids

Suspended Slab Success Build It International

Installation Wood Formwork For Concrete Slabs And Beams Of Roofing Construction Youtube

For example, slab formwork is used to build concrete slabs, column formwork is used to build concrete columns and so forth When suspended concrete slabs are constructed that are not directly supported by the ground, slab formwork is required Slab formwork includes formwork panels, stringers, joists, shores, and other supporting materials that Suspended concrete floor slab formwork system 1 Suspended Concrete Floor Slab Formwork SystemSuspended concrete slab formwork moladi Insitu floor Suspended slab formworksystemmoladi designer of a unique patented plastic formwork system has recently design a newSuspended slab formwork system for casting reinforced Suspended concrete slabs Floor slabsSuspended concrete slab formwork All suspended concrete slab formwork wholesalers & suspended concrete slab formwork manufacturers come from members We doesn't provide suspended concrete slab formwork products or service, please contact them directly and verify their companies info carefully

Irp Cdn Multiscreensite Com 2909d05a Files Uploaded Vu981 Pdf

Concrete Formwork For Slabs

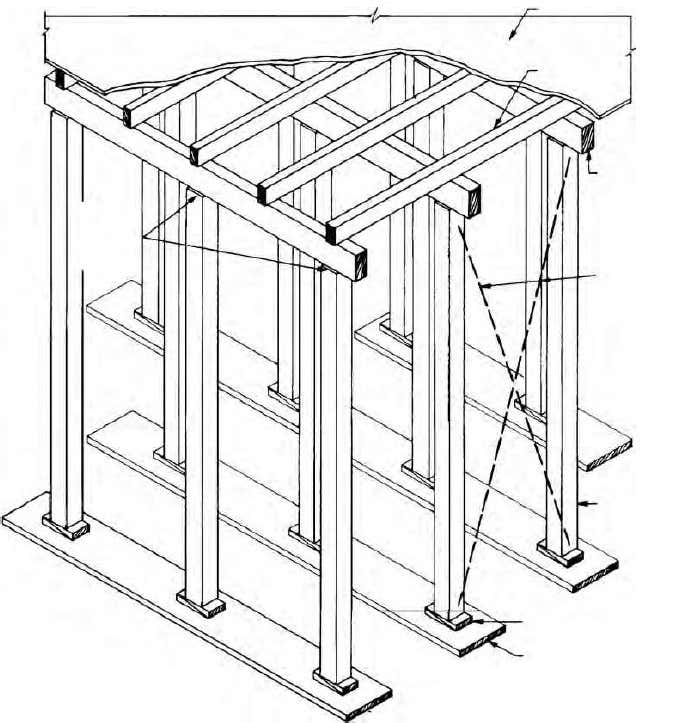

2 inches What is a suspendedThe 6 inch suspended slab in detail 21 weighs 75 pounds per square foot but the formwork should be designed to carry psf due to the weight of workers and equipment used during pour That is why concrete formwork for suspended slab has a lot more columns and beams compared to the normal residential floor framingOn the right is the slab formwork for a suspended concrete slab to a multi story building, but this system of concrete formwork could just as easily be used on an owner builder house What you see is a series of steel frames with cross braces holding them together They have adjustable screw jacks at the bottom and top

Formwork Concrete Slab And Beam Construction Shuttering System Of Slab And Beam Youtube

Suspended Slab Formwork Cassaform Construction Systems

Types of Formwork For Concrete Slab and Beam Concrete slabs are rectangular, reinforced concrete structures that can be sized in length and width, but have a smaller depth They are used for floors, roofs and bridge decksYou can choose from many different designs for a suspended slab to increase its strength and/or weightConventional Formwork Afs Redi Wall/ Dincel Insitu concrete constructions Condek/ Bondek Concrete Tilt Panel Suspended Beams & SlabsQuality Formwork Contractors in Melbourne Melbournes leaders in Formwork & Commercial Concrete Construction Please call (03) 9132 8155 Email Us Commercial Formwork We are geared to tackle all types of commercial formwork projects around Australia From multistorey developments to large government works and smaller scale shops, schools

Concrete Floor Slab Construction Process Eplan House

Structure Suspended Slab Home Building In Vancouver

The removal of formwork also called as strikeoff or stripping of formwork should be carried out only after the time when concrete has gained sufficient strength, atleast twice the stress to which the concrete may be subjected to when the formworks are removed It is also necessary to ensure the stability of the remaining formwork during formwork removalThis included formwork to the ground slab, steel fixing concrete, place of ground slab, formwork for suspended slab and upstaged beam, Dincel installation with walls poured, pour main concrete slab, steel fix of main slab and concrete pour Contact us for assistance with all your suspended concrete slab requirements Call 0402 336 586 or 0437The shuttering/formwork can be stripped out 3 days after the concrete is poured This allows access to the construction zone up to 3 weeks earlier than any other suspended slab system The Speedfloor concrete floor system is a proven performer in all types of construction

Analyzing The Efficacy Of A Suspended Concrete Slab In Formwork And Concrete Construction Asfct Concreting Service

Concrete Slab Wikiwand

Concrete Form Group is a proud family owned and run business with over 25 years of extensive experience in the formwork construction industry Based in Sydney, Form Group specialises in residential and commercial highrise projects We can provide a complete structure packages to create a single point of responsibility making the buildingThen the slab setting out will be done The offsets marked on the slab formwork used to do either setting out work Further reading on setting out of slab shall be done by article Methods of Setting out of Slabs After all the checkings are completed we proceed with concrete pouring Concrete

Architectural Aluminum Formwork System If Formwork System Kitsen Fastform

Concrete Construction Smarter Homes

Why Wouldn T You Use Modular Slab Formwork Systems

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

Adjustable Prop Vertical Robust Suspended Slab Formwork System Adjustable Prop Manufacturer From China Cccc Fwk International Formwork Corporation

Suspended Floor Flying Table Forms Concrete Slab Shuttering Panel Formwork Buy Kitsen Flying Table Forkwork Forms Suspended Floor Slab Formwork Product On Alibaba Com

Q Tbn And9gcstfx Rzcjfxnpwdzm9ih1flj47wyelb0j8gzsjt9jw Xwpgsin Usqp Cau

Concrete Slab Formwork Buy Concrete Slab Formwork Deck Formwork Steel Props Product On Ngm

Q Tbn And9gctm Hteekppjbih3ph6iojfamqqelgwhko9qgll5wdg12ugfmme Usqp Cau

Portable Used Steel Suspended Floor Slab Concrete Pouring Table Formwork System High Strengh Steel And Birch Ply Buy Flying Table Formwork Used Steel Shuttering Material Waffle Slab Formwork Product On Alibaba Com

1

R Development Floor Beam And Suspended Slab Formwork Work Course Of Conventional Timber Formwork Shuttering Works Windown Installation Service

James Loder Construction Blog Site Visit Suspended Slabs And Suspended Ceilings

Peri Gridflex Slab Formwork System Youtube

Vsc Formwork Concreting

Suspended Slab And Beams Method Of Construction Constructupdate Com

5 Things To Look For When Inspecting A Suspended Concrete Slab

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

First Floor Concrete Slabs What You Need To Know Eco Built

What Is Formwork For Slab My Decorative

Suspended Concrete Floor Slab Formwork System

File Slab Formwork Tables Jpg Wikimedia Commons

Suspended Slab Formwork Cassaform Construction Systems

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

4 1 Formwork For Concrete Slab

Concrete Slab Abis

Concrete Formwork Enable Contracting

Safety Suspended Slab Formwork Shifting Trolley With Hydraulic Power

Formdeck Permanent Metal Tray Formwork Formdeck Dandenong South Vic 3175

File Suspended Slab Blockwork Jpg Wikimedia Commons

R Building Constructing Concrete Floor Slab Building Course Of Suspended Slab Formwork Metal Reinforcement Windown Installation Service

Aluminium Alloy Formwork For Slab China Aluminium Formwork Slab Formwork System Made In China Com

Suspended Slab Construction Process Traditional Timber Formwork Steel Rebar Concrete Process Redmountains

Method Statement For Formwork Reinforcement And Concrete Works

Concrete Slab Steel Formwork Shuttering Materials Buy Mobile Scaffold Suspended Scaffolding Ladder Cripple Scaffolding Product On Alibaba Com

Design And Calculation Of Formwork Requirement Of Slabs Structville

Concrete Formwork Slab Shoring System For Construction Buy Concrete Slab Formwork Scaffolding System Suspended Concrete Fomwork Safety Concrete Formwork For Suspended Slabs Product On Alibaba Com

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

What Is Slab Formwork

Formdeck By Formcraft Pty Ltd Archello

Skydome Geoplast

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

Formwork To Suspended Slabs Beams And Columns Youtube

Stramit Condeck Hp

Formwork Bearers

Suspended Slab Formwork Cassaform Construction Systems

How Are Suspended Slabs Built Quora

First Floor Slabs Concrete Slab Contractors Near Me

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Suspended Concrete Floor Slab Formwork System

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

N S Concrete Sydney Suspended Concrete Slab Specialists 40 Yrs Exp

Suspended Slab Success Build It International

Kingflor Rf55 Fielders

When To Remove Concrete Formwork Civilblog Org

Concrete Floor Slab Construction Process The Constructor

Flexible Slab Formwork Systems Timber Beam Plywood Material S Hs

Q Tbn And9gct 1b6uyaco2szeh5phcdwah Prbgcjhxxxjkxu7brkxsn5krht Usqp Cau

Formwork Contractors Melbourne Suspended Slabs 03 9132 8155

Shoring Support For Concrete Slabs Efco Formwork Solutions

Concrete Slab Floors Pro Rib And Block

Timber Beam H Concrete Slab Formwork Convenient System With High Productivity

Drop Head Shoring System Formadeck Ulma Usa

China Kitsen Modular Slab Edge Formwork On Suspended Slabs China Slab Formwork Formwork Panel

Suspended Slab Construction Process Traditional Timber Formwork Steel Rebar Concrete Process Youtube

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Concrete Formwork Removal Time Specifications And Calculations The Constructor

N S Concrete Sydney Suspended Concrete Slab Specialists 40 Yrs Exp

Concrete Slab Or A Timber Joisted Floor Which Is Best Partridge

Lysaght Bondek Formwork Structural Decking Composite Slab System

Concrete Slab Floors Yourhome

Timber Beam H Concrete Slab Formwork Systems For Building Exterior Wall

Concrete Formwork Alternatives For Construction Pros

File Suspended Slab Formwork Jpg Wikimedia Commons

China Exporter Suspended Concrete Slab Formwork Systems Buy Slab Formwork Slab Formwork Systems Suspended Concrete Slab Formwork Product On Alibaba Com

Construction Suspended Concrete Slab Formwork Systems Shifting Trolley

Light Weight Flying Table Formwork Concrete Slab Systems Longer Life Span

4 1 Formwork For Concrete Slab